Testing

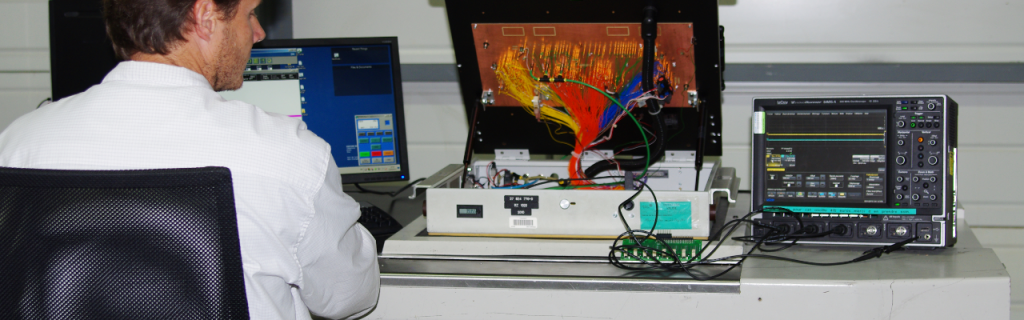

Our engineers define and execute the necessary tests and calibrations on the most complicated electronic products. They design ad hoc testing machines and testing sequences. This know-how ensures our customers with products that are matching with the highest tests rate possible, providing a high level of quality right after the fabrication.

Many tests are mastered

- Electronic tests

- Implementation of interfaces for operational tests

- Test sequences development

- Equipments validation based on the Six Sigma principles (Reproducibility, Capability, mechanical strains, R&R)

- Test coverage calculation

- Operational test

- CAN/LIN/Serie/Most/Apix/Ethernet communication

- Step by step engine calibration (Magnetic offset)

- Fuel/T° gauge calibration

- Test of the loudspeakers

- Test of the LED (Chromatic details)

- Test using JTAG (Joint Test Action Group)

- EEPROM management (Electrically Erasable Programmable Read-Only Memory)

- Input/output analog test

- Test mechanism for ASIL

- Multimedia equipments test

- Test of the GPS

- Test of the Bluetooth

- Test of the Wi-Fi

- Test on video signals

- Test of high-tension equipments (hybrid car batteries management system (600V – 200A))

- Radio-frequencies test

- Test of vision equipments

- Vibro-acoustic test

Our testing facilities

- Operational tester

- Spectrum analysts

- Oscilloscopes