Test equipments

FCT Gen 2.2

- Pneumatically and electrically powered

- Minimized footprint for SMD line integration

- Fixture interface changeover time (< 2 min)

- Low cost of interfaces

- Conveyor adaptable in width for each panel size (378mm x 400mm)

- No flexible connection between top and bottom (report nail)

- Reduced cable lengths

- Compact design (840mm wide)

- Interchangeable product interfaces limit project cost impact

- The GECOE sequencer allows to test several cards in parallel (FCT cycle time SMD cycle time)

- RGB colour test with spectrometer

- Upper and lower test points on the control panel

- Pairing interfaces with the product to be checked

- Handling time approx.. 4sec (machine cycle time excluding tests)

Radiofrequency tester

It was specially developed to test a multimedia and RF product.

This product is characterized by a presence of video entries (Rear view camera, Ipod input, …) and audio, as well as by the presence of RF modules.

These RF modules add to the product the functions:

- WIFI, which allows connection to the network,

- Bluetooth, which allows you to pair a phone to the car, to make hands-free calls,

- GNSS, which allows the location of the vehicle by satellite

The tester is equipped with GNSS simulation instrument to check the sensitivity.

The RF Wi-Fi equipment supports the reception / transmission tests in A / B / G / N standard in the 2.4 GHZ frequency range.

In terms of Bluetooth standard, we test the product in audio profile with frequency measurements, SNR, SINAD then EDR2.1 data profile with measurements of Frequencies, 2 Mbits BER.

To ensure a good test environment, all the interfaces are faradised, the measurements being either radiated or duct.

All of this complex equipment is shared 100% onto the multiple cages to reduce testing costs.

Key fob test

The tester allows checking functionality and performance of the « plip » or the key head.

To do this, it must be possible to test the Faraday cage product with a large radio frequency spectrum.

Configuration conformity test including the vision control of the logo, on this tester we find:

- Button functionality test

- The 315-433 MHz radiofrequency test is done under the ASK / FSK communication protocol depending on the country of destination.

- Transponder Detection and Configuration (125 KHz)

- RF amplitude, frequency and harmonic control

- Decoding and control of frame compliance

Note that all these tests are performed in a Faraday cage with attenuation – 40 dB.

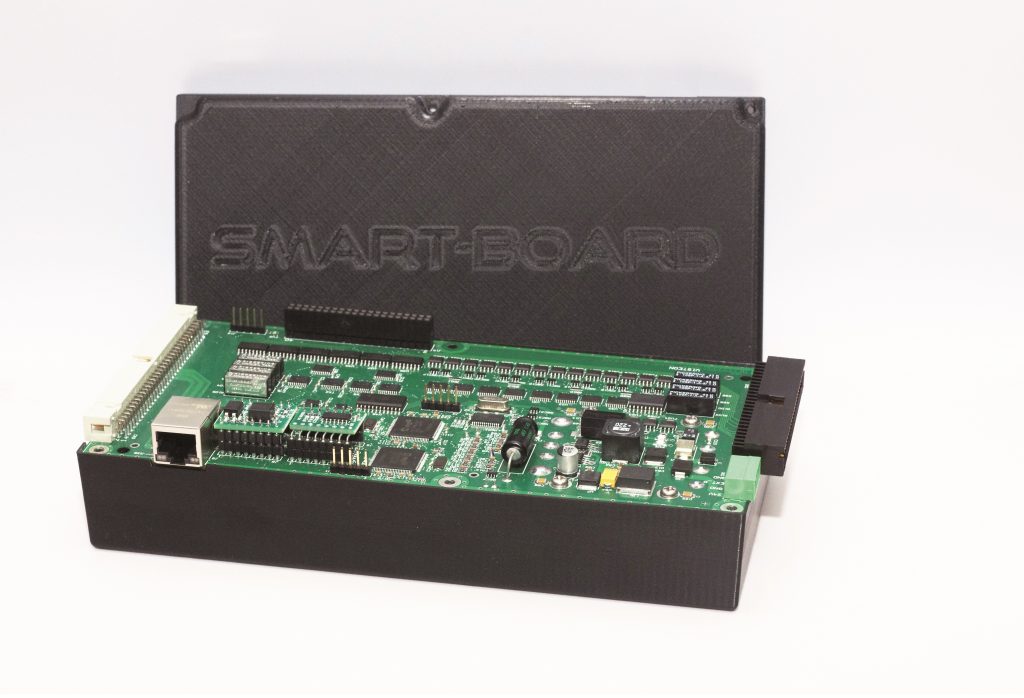

Smartboard

- Communication on an Ethernet & USB bus

- Power from 10 to 24V (min: 200W)

- Supply power (6 to 18,5V) to a product with a 1mV resolution and a max current going up to 6,5A

- Tension control : +/-5mV

- Electric current measurement with a 0.1µA resolution

- Inputs and outputs for the products control and the product diagnosis

- Inputs and outputs for the automation

- 2 customizable* CAN buses (High Speed or Low Speed) with a maximal speed going up to 2 Mbits/s and the UDS protocol integration

- 1 LIN bus (Master)

- 1 UART bus

- Use of Ethernet communication to reduce the cycle time.

- Power boosting, tension control, programmable current limit.

- Better resolution on voltage measurement.

- Ability to use the Smartboard autonomously (the needed software can be programmed on a SD card).

- Software easily updated.

- Adaptable and evolving platform, expansion bus available to add new cards.

Handler

- Powered by pneumatic or electric Vacuum

- Works with the Aeroflex tester or other 19″-rack equipments

- Energetic compatibility

- Compatible size with OEM equipments

- Full accessibility for the maintenance operations

- Easy and quick interfaces interchangeability (SMED)

- Small costs for interfaces

- Adaptable conveyor in width for each pannel size (automatic option available)

- Can receive big sized panel (300mm x 356mm)

- No adaptable connexion between top and the bottom (top bottom connection)

- Reduced cable length

- Strong design

- The handler is available in multiple versions to fit your needs.

- Its flexibility on different testers.

- Our handler has been design to come over your equipment without layout change.

- The commutable accessories dedicated to a product will lower your project cost impact.

- The top bottom connections and the reduced cable length grant an optimal test performance and a good test reliability.

- The handler is easy to use in its entirety.